eNPure...Your Source for the HydroFLOW™ Water Conditioner

A Treatment Program for Sludge Dewatering Applications

Improve dewatering operations and protect your sludge dewatering equipment from the harmful effects of struvite scale with HydroFLOW™ to save thousands of dollars in annual operating costs.

HydroFLOW™ provides a unique solution to sludge dewatering applications, in an eco-friendly, cost savings package. Its oscillating signal improves sludge flocculation and dewatering with a corresponding reduction in polymer consumption and increase in dry solids concentration. Simultaneously, dewatering operations that are subject to struvite scale are protected from expensive downtime and maintenance.

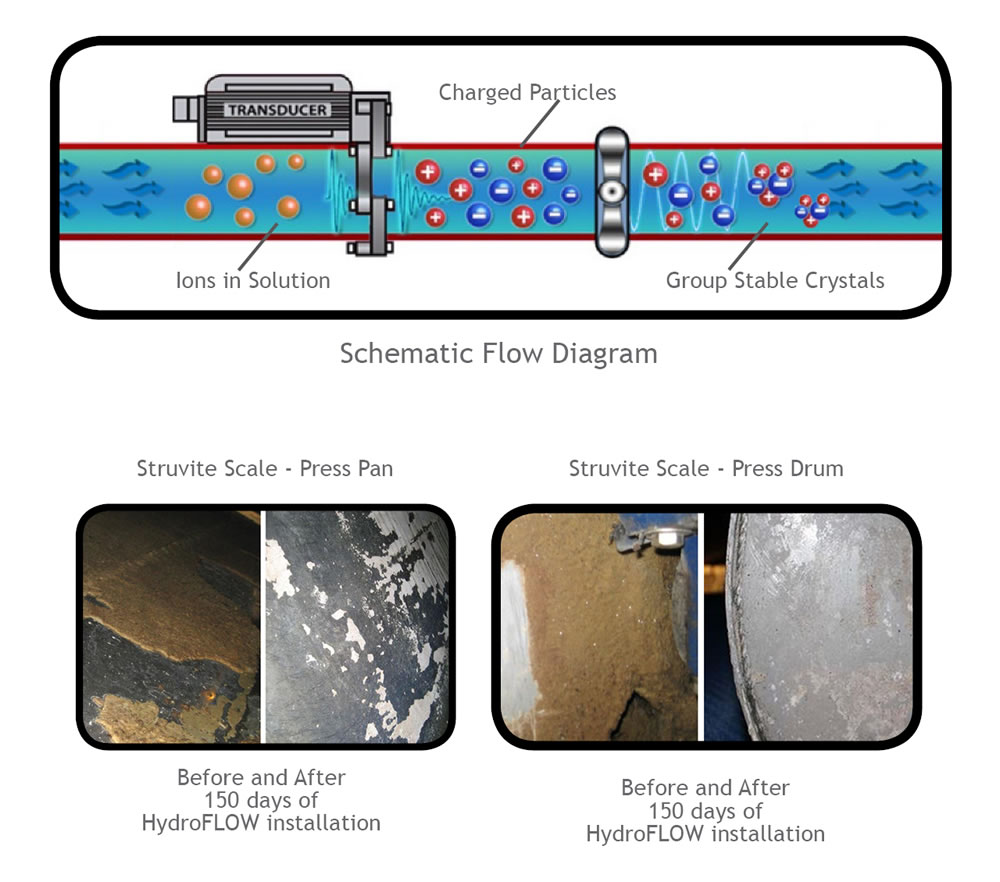

Easily installed on the exterior of any piping system or pipe material, the HydroFLOW device employs a ferrite ring to apply an oscillating 150 kHz frequency that penetrates the pipe wall and travels both up¬stream and downstream from the point of installa¬tion. The wastewater within the piping system, acts as a conduit to propagate the signal throughout the system, conditioning the water, whether it is moving or stationary. Testing has proven that the Hydropath signal is more efficient and effective than similar water conditioning technologies.

The wastewater stream typically contains miner¬als, such as calcium carbonate or struvite, dissolved in the form of ions. Evaporation concentrates the dissolved minerals. When the temperature of the solution increases, or its pressure drops, the solution becomes supersaturated which causes the dissolved ions to precipitate out of solution, adhering to piping and equipment surfaces in the form of scale.

The HydroFLOW™ signal induces the dissolved miner¬als, such as struvite, to cluster and precipitate as stable crystals that remain in suspension and do not adhere to piping and equipment surfaces. Likewise, the oscillating signal suppresses the surface charge of the suspended particles, allowing them to coagulate and agglomerate with less polymer. And lastly, the signal disrupts the growth of bacteria, causing the cell walls to rupture, aiding in the mineralization of waste activated sludge.

The HydroFLOW™ Water Conditioner: an easily installed, eco-friendly device that improves dewatering operations and inhibits the formation of Struvite, without costly treatment programs.

Installed on the exterior of any piping system or pipe material, the HydroFLOW™ device employs a ferrite ring to apply an oscillating 150 kHz frequency that penetrates the pipe wall and travels both upstream and downstream from the point of installation. The water within the piping system, acts as a conduit to propagate the signal throughout the system, conditioning the water, whether it is moving or stationary. Testing has proven that the HydroFLOW™ signal is more efficient and effective than similar water conditioning technologies.

The HydroFLOW™ signal induces the dissolved minerals to cluster and precipitate as stable crystals that remain in suspension and do not adhere to piping and equipment surfaces. Likewise, the signal disrupts the growth of bacteria and algae, causing them to perish; biofilm colonies detach from pipe and equipment surfaces. Independent studies have confirmed that the HydroFLOW™ signal, with no or minimal use of biocides, inhibits the growth of bacteria and algae in circulating systems by up to 99.7%.

The suspended particles, either mineral or biological, are filtered or flushed out with the process blowdown.

Benefits

- Elimination of Downtime from Struvite Scale: The oscillating 150 kHz signal protects dewatering equipment form Struvite scale, resulting in greater uptime and reduced maintenance costs.

- Reduced Polymer Consumption: The HydroFLOW™ signal induces better flocculation of suspended solids, reducing polymer consumption on average by 20% to 25% and saving operating expenses.

- Improved solids Concentration: The HydroFLOW™ technology has demonstrated the capability to increase dry solids by 2%-3%, resulting in reduced disposal costs.

- Facilitates Mineralization of waste Activated Sludge: Dryness of dewatered sludge is most often limited by water retained within the cell walls of microorganisms. HydroFLOW™ has demonstrated the capability to breakdown these cell wall, releasing contained water, improving solids dewatering, and reducing disposal and operating costs.

- Remineralization / softening of existing scale: Heavily scaled systems are more easily cleaned after the installation of HydroFLOW™, resulting in reduced maintenance costs for press drums, flights, and pans. The HydroFLOW™ technology softens existing struvite scale, facilitating removal without damage to equipment from harsh chemicals or abrasive cleaners. Left alone, scale will dissolve or be removed by agitation from turbulent flow.

- Asset protection: Protection of equipment from accumulated scale, eliminates the need for expensive clean¬ing and downtime from reduced capacity and wear. Premature failure and replacement of dewatering equipment is often avoided, deferring future capital expenditures, conserving capital, and improving return on investment.

Case Studies:

![]() Struvite Scale control, City of Denver, CH2M Sep 2017

Struvite Scale control, City of Denver, CH2M Sep 2017

![]() Sludge Dewatering Polymer Reduction, New Hampshire WWTP

Sludge Dewatering Polymer Reduction, New Hampshire WWTP

![]() Struvite Scale control, City of Orlando WWTP

Struvite Scale control, City of Orlando WWTP

![]() Struvite Scale control, City of Tulsa WWTP

Struvite Scale control, City of Tulsa WWTP

![]() Water Environment Federation (WEF) Award Winner 2017, Press Release

Water Environment Federation (WEF) Award Winner 2017, Press Release

![]() WEF Award Winner 2017 - Struvite Scale Control

WEF Award Winner 2017 - Struvite Scale Control

CLICK HERE to request our HydroFLOW™ Technology Report (193 pages) or additional information.